Cov khoom

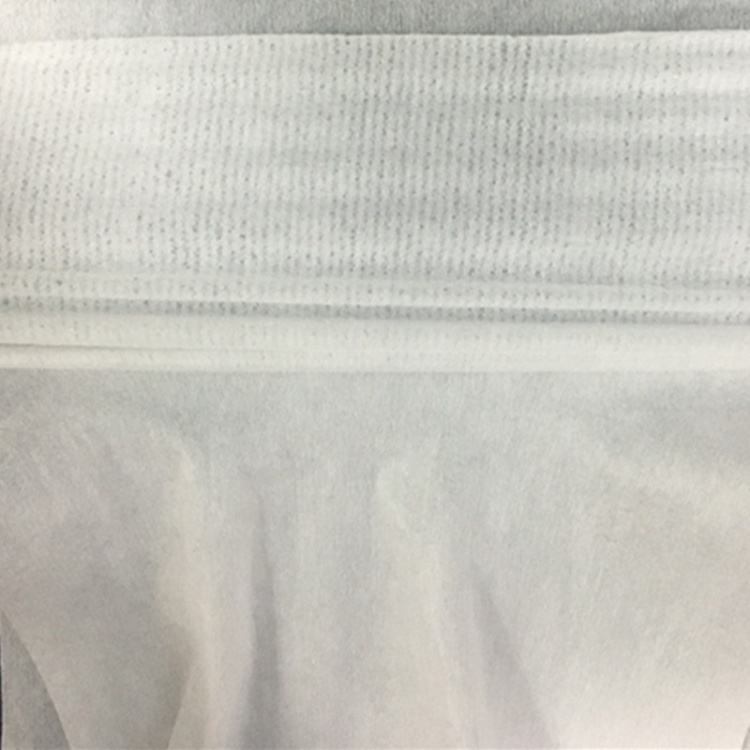

Elastic Nonwoven 100% PP Npuag

Ib qho LMPET (tsawg melting point polyester) fiber ntau thiab siab elastic PP fiber ntau yog ua ke nyob rau hauv ntau yam sib txawv los tsim ib tug buffered composite nonwoven ntaub. Cov ntaub thiab elastic polymer zaj duab xis tuaj yeem ua ke ua tsaug rau daim ntawv thov kub nias. Lub thickness thiab sib tov piv ntawm cov khoom sib xyaw yog muab rau hauv kev txiav txim siab thaum ntsuas nws cov khoom siv kho tshuab thiab cushioning zoo. Kev soj ntsuam kev sib txuas lus thiab kev ntsuam xyuas tev tawm qhia tau hais tias muaj kev sib raug zoo ntawm cov yeeb yaj kiab polymer thiab cov ntaub tsis yog ntaub.

Elastic nonwoven npuag cov txiaj ntsig

Lub elasticity ntawm elastic nonwoven fabrics yog lub cim xeeb ntawm fiber ntau positioning, uas generates nro. Yog li ntawd, siab ductility ntawm ntau tshaj 200% thiab ib tug me me retraction quab yuam yog lub ntsiab feature ntawm no elastic nonwoven fabrics. Yog li no tus yam ntxwv ntawm siab ductility thiab tsis tshua muaj tensile lub zog tau siv rau ntau yam khoom, ua rau tus neeg hnav kom lo thiab tshem tawm strain los yog ua xua los ntawm elastic siv.

Nta ntawm Elastic 100% PP nonwoven ntaub

1. PP elastic nonwoven fabrics yog ceev tensioning tsis ua rau cov xov;

2. Hom pp nonwoven no kuj muaj qhov ceev nro stabilization;

3. Elastic pp non woven fabrics twb tau txhim kho ntaub lub zog thiab super elasticity;

4. Nws kuj yog qhov siab nruj thiab tawg taw tes;

5. Tsis tas li ntawd, nws qhov nro poob yog me me thaum lub sij hawm stretching;

Cov txheej txheem ntawm elastic nonwoven ntau lawm

1. Nyob rau hauv tshwj xeeb loj mesh qauv yuav ua tau tiav los ntawm needling.

2. Qhov tseeb, qhov elasticity ntawm cov khoom siv vim yog siv cov crimp fibers.

3. Nyob rau hauv txoj kev yaj-tshuab, cov elastic nonwoven fibers raug coj ncaj qha los ntawm polymer.

4. Nonwoven nto yog tsim los ntawm kev npog ib los yog ob sab ntawm qhov chaw nrog cov tshuaj uas lo rau hauv av los ua ib txheej zaj duab xis.