Matla ke motheo oa bohlokoa oa ho phela le nts'etsopele ea batho, o tsamaisang tsoelopele e tsitsitseng ea moruo oa lefats'e le ntlafatso e tsoelang pele ea boleng ba bophelo ba batho. Liaparo, tse ka 'nang tsa bonahala li sa amane le sebaka sa matla a matla, li phetha karolo ea bohlokoa ka ho eketsehileng ntlafatsong ea theknoloji ea matla.

Liaparo, tse nang le litšobotsi tse ikhethang tsa 'mele le lik'hemik'hale, li bontšitse tebello e pharaletseng ea ts'ebeliso masimong a matla a khale a kang matla a mocheso le peterole, hammoho le masimo a macha a matla a kang matla a moea, matla a hydrogen, photovoltaics le libeteri. Lisebelisoa tsena ha li ntlafatse matla a ho fetola matla feela, empa li boetse li khothalletsa tsoelo-pele e tsitsitseng ea theknoloji ea matla. Ka keketseho e tsoelang pele ea tšebeliso ea masela tšimong ea matla, lisebelisoa tse ncha tsa fiber le mekhoa e mecha ea masela e ntse e tsoela pele ho hlaha. Tshebetso le tshebetso ya masela a matla a ntse a ntlafala, a bapala karolo e ke keng ya nkelwa sebaka tlhahisong e bolokehileng, tshebetsong e hlwahlwa, phetiso e tsitsitseng le maemo a mang a indasteri ya eneji.

Pontšong ea CINTE24, palo e kholo ea masela a matla le eona e ile ea bontšoa sebakeng sa lipontšo tsa masela a tsoetseng pele a theknoloji, ka sepheo sa ho khothaletsa puisano le tšebelisano lipakeng tsa karolo e ka holimo le e tlase ea ketane ea indasteri, ho potlakisa phetoho ea katleho ea masela a indasteri, lihlahisoa tse ncha, mahlale a macha le lits'ebetso tsa maemo a holimo, le ho thusa ho aha sistimi ea phepelo ea matla a fapaneng le a hloekileng.

Masela a na le ts'ebeliso e pharaletseng le ea bohlokoa meepong ea mashala, oli le khase ea tlhaho, tlhahiso ea motlakase le phetisetso, e bapala karolo e ntle ntlafatsong ea theknoloji, ts'ebetso e sebetsang hantle, tlhahiso ea polokeho, paballo ea matla le phokotso ea tlhahiso indastering ea matla. Lefapheng la matla a mocheso, ts'ebeliso e kholo ea theknoloji ea filthara ea mekotla ka har'a limela tsa matla a mocheso e fokolitse haholo ho tsoa lerōleng; Tlhokahalo ea "ultra clean emissions" e khothaletsa tsoelo-pele ea theknoloji ea lisebelisoa tsa filthara, ka palo e kholo ea ts'ebeliso ea lisebelisoa tsa filthara ea "ultra-fine surface gradient", lisebelisoa tsa sefa sa membrane, joalo-joalo, le ntlafatso e tsoelang pele ea mahlale a fapaneng a tiiso; Ho feta moo, ts'ebeliso ea marang-rang a matla a phahameng a polyester fiber flexible mesh moepong oa mashala o ntlafalitse ts'ebetso ea ho khutlela morao le boemo ba tiisetso ea polokeho ea sefahleho sa morafo se hlophisitsoeng ka botlalo; Tšebeliso ea thepa ea filimi ea khase ha ho hahoa mashala a mashala a feme ea matla e thibela ka katleho ho hasana ha lerōle la mashala; Mabanta a conveyor a matlafalitsoeng a masela ke lisebelisoa tsa bohlokoa tsa ho tsamaisa mashala lifemeng tsa motlakase

Sebakeng sa phetisetso ea matla, li-conductors tse matla a holimo li matlafatsa matla a ho jara mehala ea likhoele tsa phetiso, ha lisebelisoa tsa ho phuthela ka mohala le pampiri ea ho kenya letsoho li netefatsa polokeho le botsitso ba phetisetso ea matla; Sutu e sireletsang e sireletsa ka katleho polokeho ea basebetsi.

Ka indasteri ea peterole, li-hoses tse matlafalitsoeng ka fiber li fana ka tšireletso bakeng sa lipalangoang tsa oli; Likoahelo tse thibelang ho bola le tse sa senyeheng le lisebelisoa tsa ho lokisa liphaephe li eketsa bophelo ba lisebelisoa; Masela a khethehileng a sebelisetsoang ho hloekisa le ho arohana ho ntlafatsa katleho ea oli; Bopaki ba ho phatloha le masela a anti-static a netefatsa polokeho ea tlhahiso ea peterole.

Ntlafatso ea indasteri e ncha ea matla e atolositse bophara le botebo ba ts'ebeliso ea thepa ea masela tšimong ea matla. Ka mokhoa o ntseng o eketseha oa li-turbine tsa moea tse kholo le tse bobebe, hammoho le nts'etsopele e potlakileng ea matla a moea a tsoang lebōpong la leoatle, sebaka sa ts'ebeliso le tekanyo ea fiber ea carbon ka har'a mahare a turbine ea moea li ntse li eketseha butle-butle. Ka mabaka a moruo, li-blades tsa morao-rao tse tloaelehileng li entsoe ka fiberglass. Leha ho le joalo, tlas'a boemo ba ho finyella litlhoko tsa ho satalla le matla, li-blades tsa carbon fiber fan li tla fokotsa boima ba tsona ka ho feta 30% ha li bapisoa le li-blades tsa fiberglass tse tloaelehileng, tse ka fokotsang boima ba li-blades le ho finyella tlhokahalo ea li-blades tse kholo tse bobebe. Ho latela lintlha tsa GWEC (Global Wind Energy Council), ha bolelele ba mahare a turbine ea moea bo feta 40m, litšenyehelo tsa lisebelisoa tse felletseng, mosebetsi, lipalangoang le ho kenya lia fokotseha. Ka hona, ho sebelisa fiber ea carbon ho etsa li-blades ho na le chelete e ngata ho feta ho sebelisa fiber ea khalase.

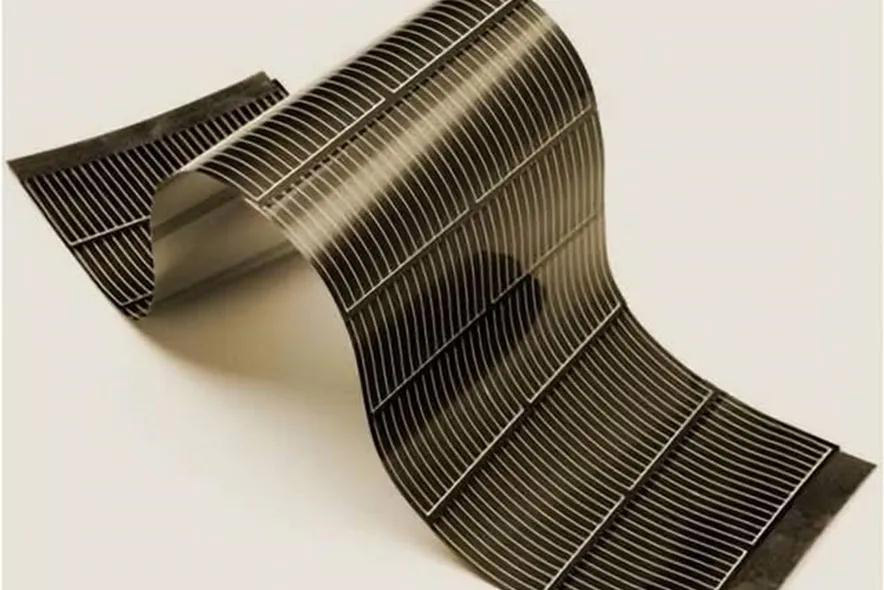

Ho phaella moo, lisebelisoa tsa carbon fiber composite, lisebelisoa tsa fiber membrane, le lisebelisoa tsa terata ha li sebelisoe feela ka mokhoa o pharaletseng mekhoeng ea tlhahiso ea photovoltaics, libeteri tsa lithium le matla a hydrogen, empa hape le likarolo tsa bohlokoa tsa lihlahisoa tsena tse ncha tsa matla. Lefapheng la photovoltaics, lisebelisoa tse entsoeng ka masela li tsoela pele ho fana ka tharollo e tsoetseng pele bakeng sa ntlafatso ea indasteri ea photovoltaic, ha likarolo tsa carbon composite thermal field li thusa ho ntlafatsa katleho le polokeho ea tlhahiso ea silicon ea crystalline; Lesela la liphutheloana le feto-fetohang le le sebetsang hantle le ntlafatsa botsitso le ho tšoarella ha lihlopha tsa lisele tsa photovoltaic; Lisebelisoa tsa fiber tse kang likhatiso tsa khatiso li sebelisetsoa ho etsa li-module tsa photovoltaic, ho fokotsa litšenyehelo tsa thepa e tala le ho ntlafatsa katleho ea ho fetola matla a khanya.

Sebakeng sa libeteri, lisebelisoa tsa karohano tse thehiloeng ho fiber li ka thibela ka katleho li-circuits tse khutšoane lipakeng tsa li-electrode tse ntle le tse mpe, ho ntlafatsa ts'ebetso ea ho tjhaja le ho lahla le polokeho ea libeteri; Lisebelisoa tsa li-electrode tsa fiber li ntlafatsa conductivity le botsitso ba sebopeho sa li-electrode; Lesela la ka ntle le hanyetsanang le mocheso o phahameng le le thibelang malakabe a ho paka le matlafatsa polokeho ea tšebeliso ea betri.

Sebakeng sa matla a haedrojene, li-separators tsa betri tse sebetsang hantle li ka sebelisoa bakeng sa tlhahiso ea electrolytic hydrogen, lisebelisoa tse nang le lisebelisoa tse phahameng tsa fiber li sebelisoa ho etsa lijana tsa polokelo ea haedrojene, 'me masela a nang le moea o motle le ho hanyetsa kutu a sebelisetsoa ho sireletsa liphaephe tsa phetisetso ea haedrojene.

Masela a mangata a sa lohiloengsplicing e bohale, bophara ba lesela le sa lohiloeng bo ka fihla ho limithara tse mashome, mochini o kopanyang oa lesela le sa lohiloeng!

Nako ea poso: Jan-03-2025