Iimveliso

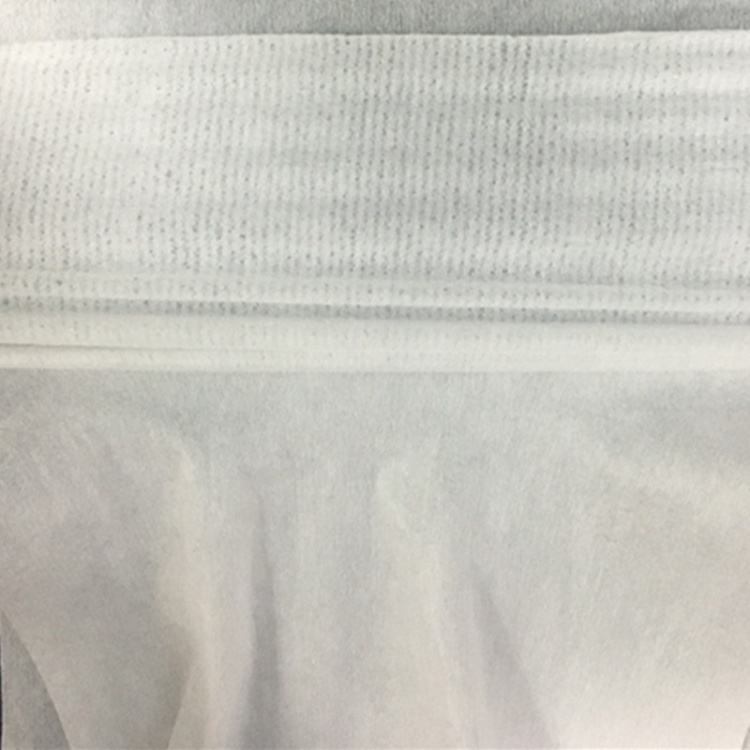

Elastic Nonwoven 100% PP Ilaphu

I-LMPET (indawo yokunyibilika ephantsi i-polyester) ifayibha kunye ne-elastic ephezulu ye-PP ifayibha zidityaniswe ngokwexabiso elahlukileyo ukwenza ilaphu elidityanisiweyo elingalukwanganga. Ilaphu kunye nefilimu yepolymer elastiki inokudityaniswa emva koko ngenxa yokusetyenziswa koxinzelelo olushushu. Ubuninzi kunye nokuxuba umlinganiselo we-composite kuthathelwa ingqalelo xa kuhlolwa iimpawu zayo zomatshini kunye ne-cushioning. Ukuqwalaselwa kojongano kunye neziphumo zovavanyo lokuxobula zibonisa ukuba kukho umanyano olomeleleyo phakathi kwefilimu yepolymer kunye nelaphu elingalukwanga.

Inzuzo yelaphu elingalukwanga elelastic

I-elasticity evela kwilaphu elastiki engalukwanga yinkumbulo yefiber positioning, eyenza uxinezeleko. Ke ngoko, i-ductility ephezulu engaphezulu kwe-200% kunye namandla athambileyo okurhoxisa yeyona nto iphambili yala malaphu e-elastic nonwoven. Ke olu phawu lwe-ductility ephezulu kunye namandla asezantsi asetyenzisiweyo kwiimveliso ezininzi, okwenza lowo unxibileyo abambelele kwaye aphelise ubunzima okanye ukwaliwa okubangelwa ibhanti elastiki.

Iimpawu ze-Elastic 100% yelaphu le-PP engalukwanga

1. Amalaphu e-elastiki e-PP e-elastiki adibanisa ngokukhawuleza ngaphandle kokonakalisa intambo;

2. Olu hlobo lwe-pp nonwoven lubuye lube nozinzo olukhawulezayo loxinzelelo;

3. Amalaphu eelastic pp angalukwanga sele ephuculwe ukomelela kwelaphu kunye nokunwebeka okuphezulu kakhulu;

4. Ikwangumda woxinzelelo oluphezulu kunye nenqanaba lokuqhawula;

5. Ukongezelela, ilahleko yayo yoxinzelelo incinci ngexesha lenkqubo yokwelula;

Iindlela zemveliso elastic nonwoven

1. Ngokukodwa izakhiwo ezinkulu zemesh zinokufezekiswa ngokuligalelwa.

2. Ngokwenyani, ukuqina kwezinto ngenxa yokusetyenziswa kweefibers zecrimp.

3. Kwiindlela zokunyibilika, iifiber elastic nonwoven zithathwa ngokuthe ngqo kwipolymer.

4. Imiphezulu engalukwanga yenziwa ngokugquma icala elinye okanye omabini omphezulu ngekhemikhali encamathela emhlabeni ukuze yenze umaleko wefilimu.